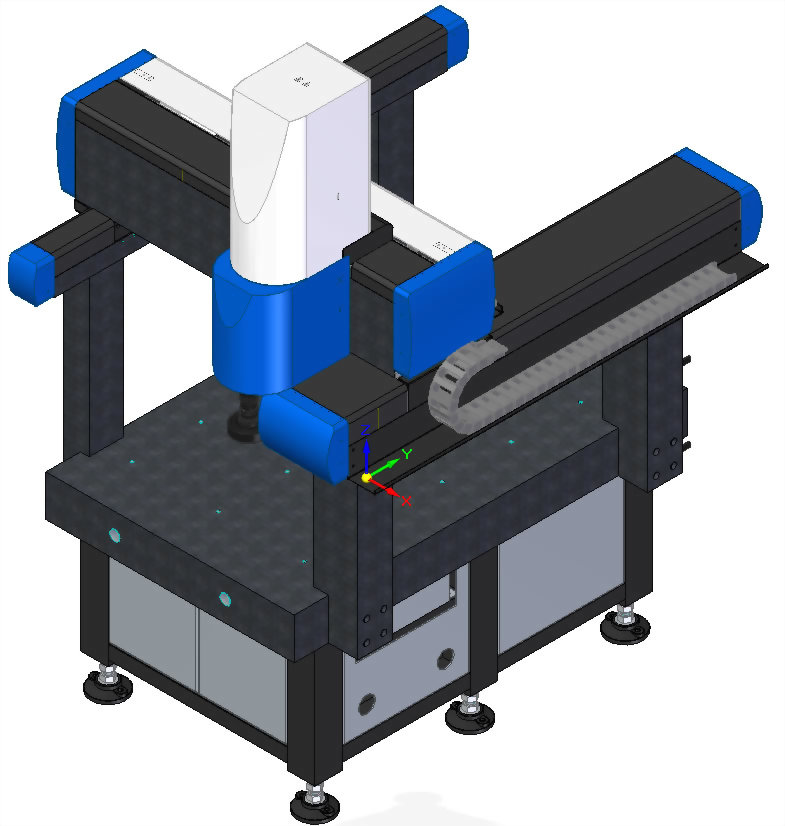

3D DCC measure machine

continuous fine feed over the entire measuring range.

moving-bridge structure provides excellent astability.

- in choosing the moving bridge structure, COMPLETE has determined the ARIES measure body design through the Finte-element meathod analysis so that machine deformation duringprobing is minimized and evened. The optimized machine design achievesa competent measuring accuracy of (3.0 +L/300)um and very smooth probing with minmum operation fatigue.

production

ARIES liner guide series High accuracy 3D

DCC measure machine

type

ARIES-564

ARIES-686

Probe

system

Renishaw

Renishaw

Profile

dimension (mm)

1250x950x2100

1350x1150x2250

Net

weight

550 KG

750 KG

Measure

range

X (mm)

500

500

Y (mm)

400

600

Z (mm)

300

400

Work

table

Granite

table

650x1150 mm

750x1350 mm

weight

350 KG

450 KG

Measure

system

Video

system

Add video system support probe system

130 pixel digital CCD CAMERA +zoom lens +LED ring

light

Probe system

Renishaw full specification probe module

and styli

CAD input/

output

Input parts CAD compare original design

data, second, the CAD output copy parts data.

Measure software

AXEL 7 is multi-function module system,

support complex and

Scale resolution

0.0005

mm (option0.0001 mm)

Measure

accuracy(um)

X/Y/Z axis : ≤ 3+L/300 (um)

Repeatability

accuracy 3um

control

system

motor

DCC servo motor+ liner guide with bearing

roller

Control system

To advance control system

joystick

Multi-function display joystick

X Y Z transmission

DCC servo motor + belt + air pad

Work environment

110V/220V ± 10% (AC) 50/60Hz (power to

earth)

Work temperature

temperature:22~24℃ ; humidity level:50~65% (no vibration)

Operator system/

language

support, WIN7 , WIN10

32/64 bit operator system: English/Chinese

Suitable for: electronic、mold、hardware processing、plastic injection、national defense technology、electrical、fixture、stamping molding、cell phone parts、display、mother board、car industry、aerospace industry.